Do you have any questions?

How can our pressure sensors improve your products? Send a non-binding enquiry now!

Point of contact:

Danny Nitzsche

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com

Pressure sensors

Pressure sensors are essential components in the automotive industry. Every new car contains around ten different types of pressure sensors, which monitor pressure in car tires, engine or transmission oil levels, seat occupancy, brake pressure and more. While traditional pressure sensors rely on rigid materials like silicon and involve complex production cycles, our functional printing at Witte Technology offers streamlined, cost-effective solutions for force measurement.

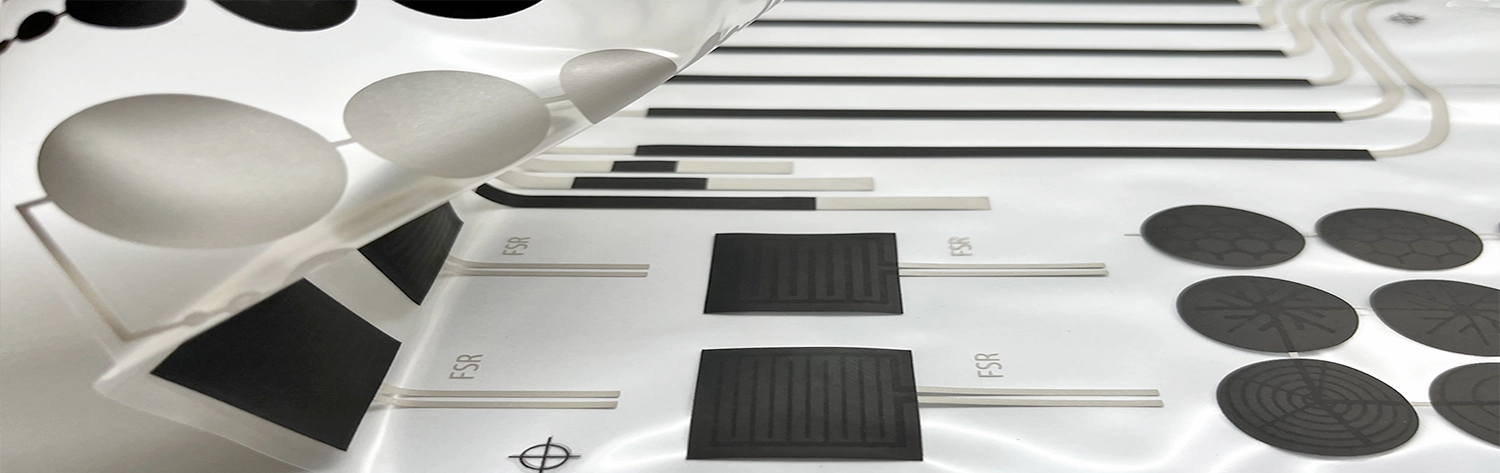

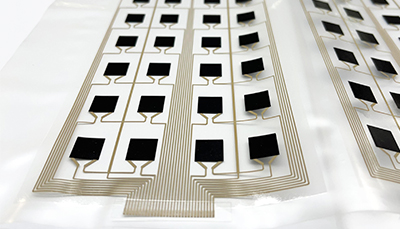

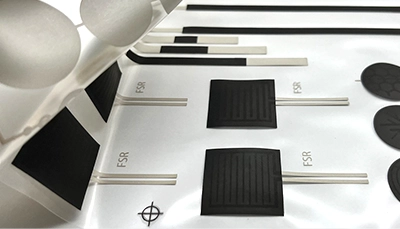

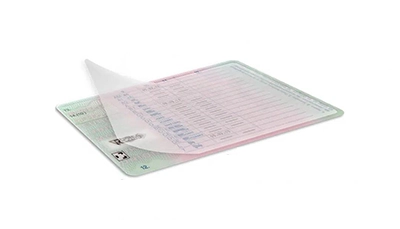

A sandwich structure consisting of two polymer films, printed silver layers and FSR (Force Sense Resistor) elements enclosing a layer of air causes contact between the upper and lower layers under pressure, resulting in a measurable change in electrical resistance. Depending on the space required and the application, this sensor can be produced in variable matrices.

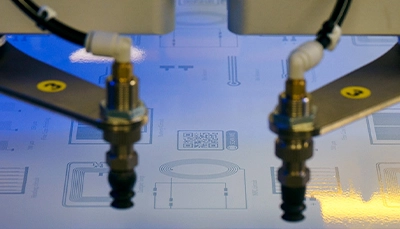

As an alternative, Witte Technology also produces piezoresistive sensors printed on polymer films. They combine a silver electrode structure, a piezo-sensitive layer, and a protective coating. This design ensures improved repeatability. Of particular interest are the highly flexible substrates, which can be used in completely new applications without any loss of functionality.

The dynamic data from both pressure sensor variants, which are printed on PET, TPU or Kapton substrates, can be transmitted completely digitally via Bluetooth or NFC using FPC or crimp connectors.

Whether as a footprint, in saddles or in robotics grippers, these are just three of many possible applications in which thin pressure sensors provide valuable measurement data over long periods of time. Their use in level measurement, for example in warehouses or supermarket shelves, is particularly promising. On significantly larger areas, such as on so-called sensor mats in buildings, train stations or public transport, the sensors enable location-resolved detection of surfaces and thus also of people flows (‘surface digitalisation’). This means they can partially replace cameras and, with their data, contribute to making these locations anonymous and more efficient.

Frequently asked questions regarding pressure sensors – FAQ

A printed pressure sensor is a sensor component that is applied to flexible or rigid substrates using industrial printing processes such as screen printing, inkjet printing or roll-to-roll printing. It detects mechanical pressure and emits a corresponding electrical signal. Printed sensors enable flat, cost-efficient and material-saving integration into a wide range of system environments.

Printed pressure sensors are used in numerous industries, such as automotive (e.g., seat occupancy detection), medical technology (e.g., pressure distribution measurement), packaging and logistics solutions (e.g., tamper detection), industrial automation, and consumer electronics. They are particularly suitable for applications where conventional sensor technology is too large, too heavy, or too cost-intensive.

Thanks to the additive manufacturing approach, printed sensors offer a high degree of design freedom, low installation height, flexible form factors and the potential for integration into existing or newly developed carrier materials. Other advantages include low weight, large-scale manufacturability, low material costs and the possibility of series production using a roll-to-roll process.

Functional inks based on silver, carbon, PEDOT:PSS, or other conductive polymers are used. Flexible film materials such as PET, PEN, or thermoplastic elastomers (e.g., TPU) are typically employed as substrates. The sensor layer structure is customized for each application with respect to sensitivity, linearity, and mechanical durability.

With proper design and adapted material selection, printed pressure sensors achieve high repeatability and long-term stability. Cyclic load tests demonstrate that the sensors continue to deliver reproducible results even after several hundred thousand load cycles. Temperature behavior, drift characteristics, and aging resistance can be optimized for specific applications through targeted material and structural design.

Point of contact:

Danny Nitzsche

Would you like advice on your printed electronics products?

Use our contact form now or call us directly!

Our experts can help you immediately.

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com