Do you have any questions?

Would you like to improve your products with temperature sensors? Request a non-binding quote now!

Point of contact:

Danny Nitzsche

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com

Printed temperature sensors

Temperature monitoring for industry and product development

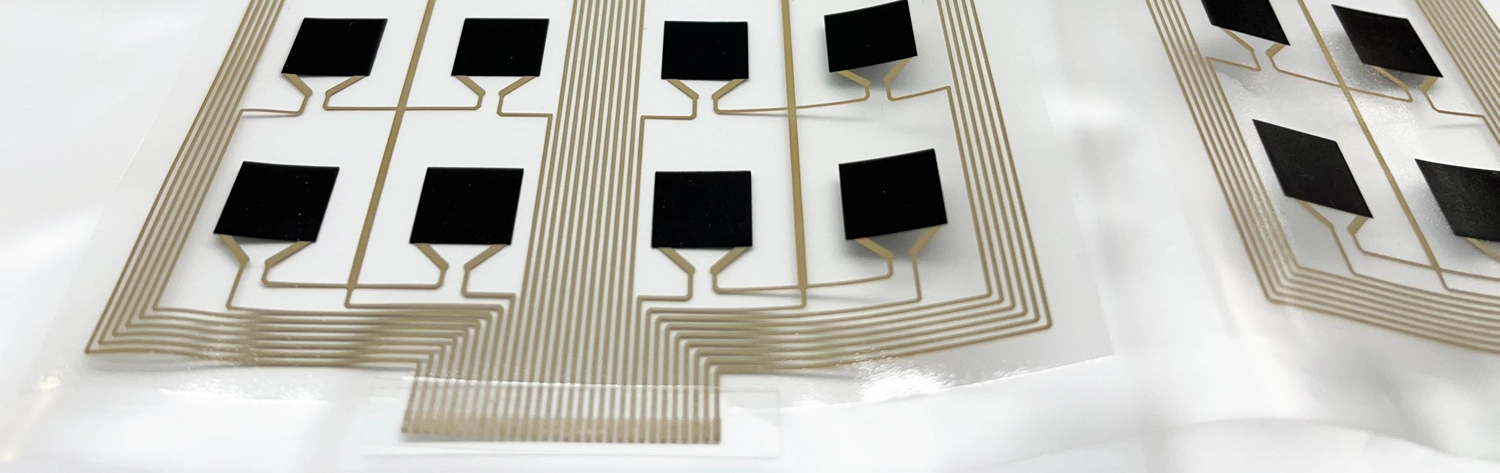

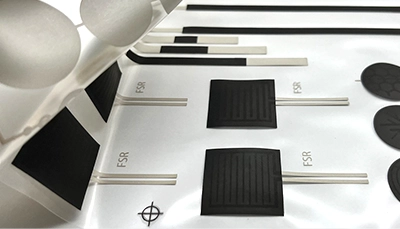

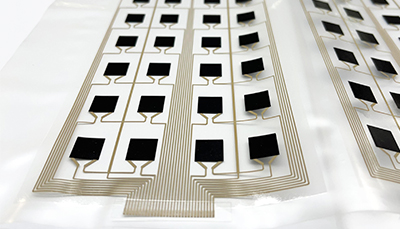

Temperature sensors play a central role in the development of new technologies. In particular, printed temperature sensors open up new possibilities for smart, cost-efficient, and precise temperature measurement. They can be integrated directly into materials and are suitable for use on flexible or curved surfaces, where conventional sensors reach their limits.

Thanks to their extreme flexibility, minimal height, and digital readability, these sensors are ideally suited for applications in areas such as e-mobility, medical technology, smart buildings, smart textiles, packaging monitoring, and building automation.

What is a temperature sensor?

A temperature sensor (also called temperature probe, heat sensor, or in English temperature sensor) is an electronic component used to measure and convert temperature values into electrical signals. It is used daily in both private and industrial applications, ranging from thermometers to temperature monitoring in machines or packaging.

In industrial environments, the focus is on reliable temperature measurement, often under difficult conditions. Industrial temperature sensors with printed electronics offer a particularly flexible solution here.

Advantages for industry & product development

The combination of printed electronics and intelligent temperature monitoring brings clear advantages for industry and development:

- Flexible & ultra-lightweight – ideal for mobile, curved or space-critical applications

- High measurement accuracy in real time

- Easy integration into existing systems, textiles or components

- Cost-effective, even for large quantities in series production

- Digitally readable via Bluetooth/NFC – perfect for mobile temperature control

How do printed temperature sensors work?

Printed temperature sensors consist of several ultra-thin layers:

- Sensitive layer with PTC (positive temperature coefficient)

- Printed electrode

- Protective layer against moisture and corrosion

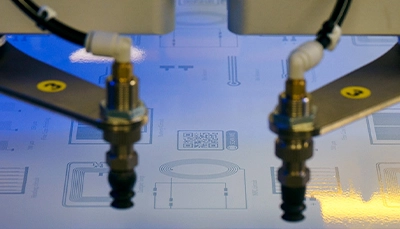

They are applied to flexible substrates such as PET, TPU, or Kapton. Through interfaces like Bluetooth or NFC, the data can be transmitted wirelessly. Perfect for modern IoT applications. Integration is space-saving via FPC or crimp connectors.

Who can benefit most from printed temperature sensors?

- Product developers seeking compact and digital sensor solutions.

- Industrial clients aiming to automate or digitalize their temperature measurement.

- Manufacturers requiring customized temperature sensors for specialized applications.

- Research & Development departments developing new smart products with integrated sensors.

Typical areas of application for temperature sensors

Printed temperature sensors are used in numerous industries:

Automotive & E-mobility

In electric vehicles and battery systems, precise temperature monitoring is crucial for safety, performance, and service life. Printed temperature sensors can be integrated directly onto battery housings or circuit boards.

- Temperature monitoring of batteries and motors

- Extends service life & increases safety

Medical technology & wearables

In smart patches, wearable health monitors, or therapeutic devices, temperature sensors ensure precise body temperature measurement—comfortable, skin-friendly, and highly flexible in use.

- Wound monitoring under dressings

- Integrated into plasters or wearable clothing

Packaging and logistics industry

For temperature-sensitive products such as food, pharmaceuticals, or chemicals, integrated sensors help document compliance with the cold chain—often directly within the packaging.

- Temperature control of sensitive goods such as pharmaceuticals or foodstuffs

- Complete cold chain documentation

Smart Building

Temperature sensors reliably measure the room temperature in heating, ventilation and air conditioning systems. In combination with smart systems, they ensure greater energy efficiency and comfort.

- Climate control with ambient temperature sensors

- Energy management & user comfort

Predictive Maintenance

In production facilities, engines, pumps, or gearboxes, temperature sensors monitor critical components. This enables early detection of overheating and helps prevent failures, making an important contribution to operational safety and maintenance planning.

Environmental and agricultural monitoring

Temperature sensors are also used outdoors. For example, to monitor soil, water, or air temperatures in agriculture or at environmental monitoring stations.

Frequently asked questions about printed temperature sensors

Printed temperature sensors are temperature-dependent electrical components that are applied to flexible substrates (e.g. PET, PI, paper) using roll-to-roll or flat printing processes. They are typically based on conductive polymers or pastes whose resistance changes depending on temperature.

A printed temperature sensor uses special materials such as PTCs, which change electrically when the temperature changes. This information is converted into a digital signal via ultra-thin, screen-printed layers.

Additive manufacturing enables printed sensors to be produced on a large scale in a cost- and material-efficient manner. They enable flexible, ultra-thin designs that can be easily integrated into existing product geometries or film composites. Ideal for smart packaging, wearables or IoT applications.

Thanks to modern materials and precise printing processes, they deliver high-resolution real-time data and are suitable for many industrial applications. At the same time, they are lighter in weight and require less space.

Depending on the material system used and calibration, printed temperature sensors typically achieve an accuracy of ±1 °C to ±2 °C in the range from -20 °C to +85 °C. For more precise requirements, multi-point calibrations and special evaluation electronics can be used.

Standard versions are designed for a temperature range of approx. -20 °C to +85 °C. For high-performance applications, systems with extended temperature ranges up to 120 °C are also available. Depending on the substrate and the printing materials used.

Printed sensors are more flexible, lighter and cheaper than conventional sensors. They can be integrated directly into products and enable completely new applications, e.g. in smart textiles, e-mobility or medical technology.

The sensors can be integrated into existing electronics via ribbon cable, conductive ink or pressure contact. Evaluation is usually carried out via simple resistance measurement (NTC or PTC behaviour) or via a digital interface during system integration. Combination with RFID/NFC or flexible battery systems is also possible.

Yes, many manufacturers offer customised temperature sensors that are tailored to specific requirements, such as shape, temperature range or material.

Point of contact:

Danny Nitzsche

Would you like advice on your printed electronics products?

Use our contact form now or call us directly!

Our experts can help you immediately.

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com