Do you have any questions?

How can our printed humidity sensors improve your products? Schedule your free consultation today!

Point of contact:

Danny Nitzsche

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com

Humidity sensors

What are humidity sensors specifically?

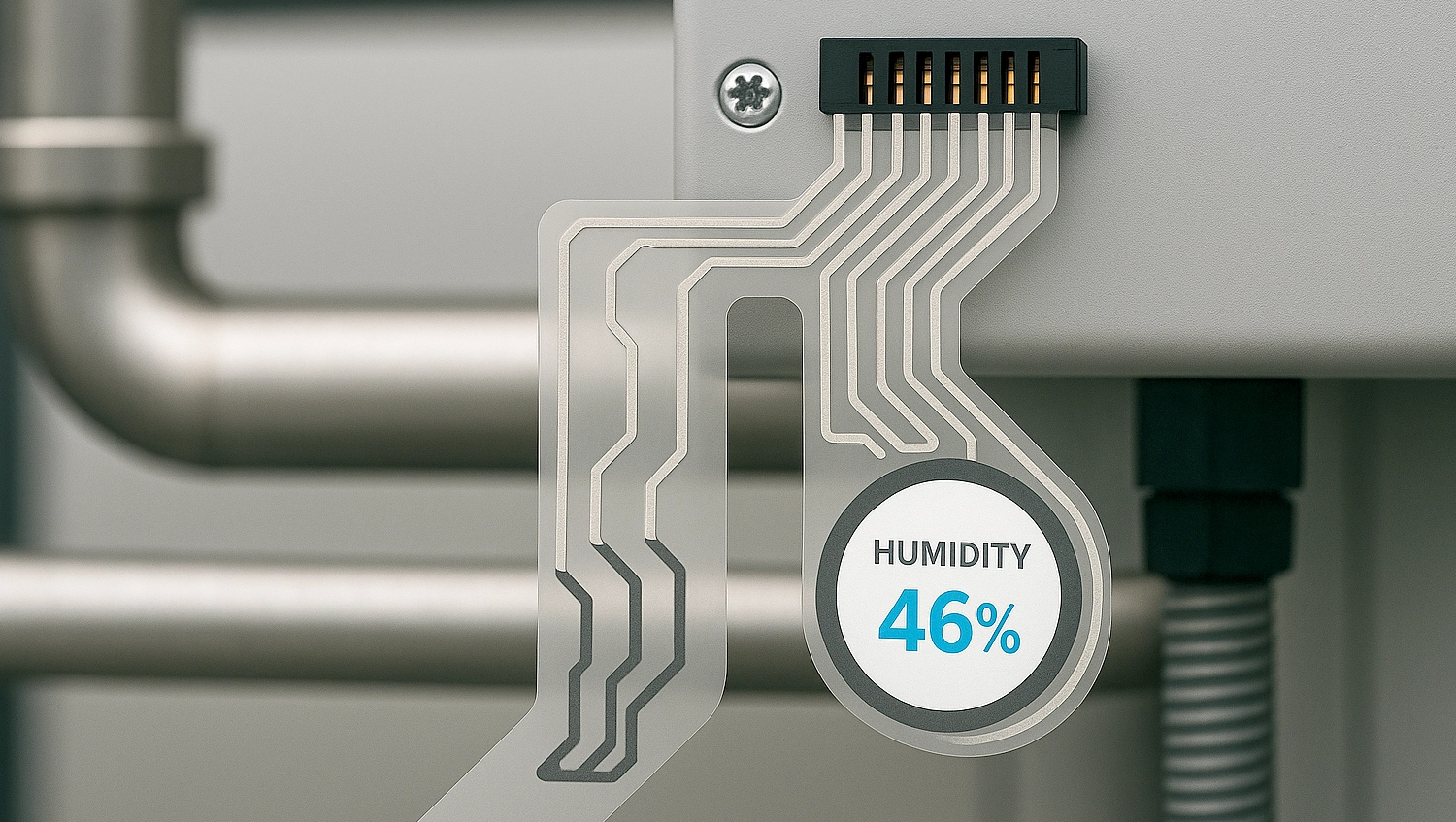

Our printed humidity sensors are innovative, extremely thin sensor components that are manufactured from printed electronics using flexible substrates. Rather than relying on traditional, often bulky sensor technology for our product, we use three-layer screen-printed IDE electrodes. They accurately register air humidity within the range of 15–85% relative humidity, even after prolonged exposure to higher humidity levels, reliably and without any loss of performance.

A practical example: The PrintElectric® humidity sensor, a product from the Witte Technology sensor series, converts moisture and humidity changes into electrical signals, enabling a wide range of modern, intelligent applications.

Advantages of humidity sensors

- Extremely thin and flexible: Can be placed onto a wide variety of surfaces or materials, e.g. flat roofs or wound dressings.

- Cost-effective: More affordable than conventional sensor technology thanks to our innovative printing processes.

- Robust and replicable: High repeatability, even under difficult environmental conditions.

- Easy integration: Compatible with standard connectors such as FPC or crimp with an efficient data transfer.

- Reliable alarm function: An alarm signal will be triggered immediately in the event of a short circuit caused by humidity and moisture. Ideal for your monitoring solutions.

Thanks to these advantages, our printed humidity sensors offer a comfortable alternative to conventional solutions, especially where low height, high sensitivity and cost-effectiveness are required.

Application areas for our printed humidity sensors

Our flexible, printed humidity sensors enable manufacturers to reliably detect moisture and liquids directly in the product, cost-effectively and easily integrated. The sensors are particularly thin, versatile and suitable for disposable products, embedded systems or smart packaging. Thanks to modern printing technology, our individually tailored solutions serve a wide variety of industries.

Automotive & E-mobility

- Leak detection

- Humidity sensors in vehicle interiors

- Monitoring of cable harnesses and control units

Medical technology & Pharmaceuticals

- Moisture-sensing wound dressings

- Wareables with built-in sensor systems

- Diagnostic kits with integrated sensor technology

- Infusion systems for leak monitoring

- Ostomy Care with fluid detection

Smart Buildings

- Moisture and leak sensors for building automation systems

- Monitoring of HVAC systems (heating, ventilation and air conditioning), walls and sanitary infrastructure

- Real-time leak detection and environmental monitoring

- Smart home devices with moisture protection

Sustainable Buildings

- Sensors prevent water leaks at an early stage

- Optimal use of energy and regulation of humidity

- Saves energy and water to meet your sustainability standards

Industrial automation

- Monitoring of switch cabinets and enclosures

- Leakage sensors in production facilities

- Humidity sensors in robotics

Smart Packaging

- Packaging with NFC/RFID for moisture control

- Smart outer packaging for electronic products

- Sensor integration in shipping packaging

- Control boards with integrated leak detection

Technology & competent production

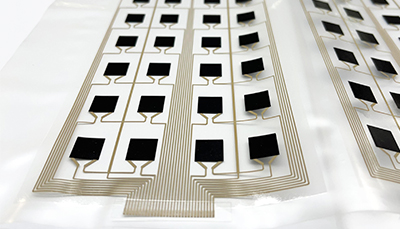

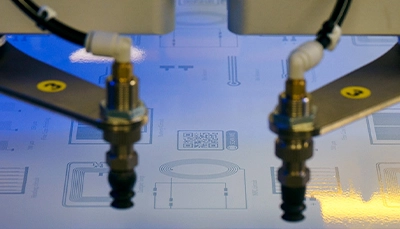

Witte Technology develops and manufactures printed humidity sensors for reliable monitoring of moisture and liquids. The sensors are based on high-resolution screen printing on flexible substrates such as PET, PEN, polyimide or TPU. Both resistive and capacitive moisture sensors are used, as well as leakage sensors that react to a wide variety of liquids. These include water, chemicals and biological solutions.

Thanks to our state-of-the-art roll-to-roll and sheet-to-sheet manufacturing, we can produce even large quantities economically. The sensor architecture is fully customisable, whether in terms of detection sensitivity, fluid type, integration into existing systems or material properties such as chemical resistance and medical compatibility.

Witte Technology offers individual, scalable solutions for manufacturers who want to integrate smart monitoring into their products.

Printed leakage sensors

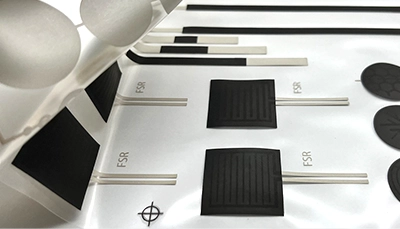

Composition

- Printed with: silver, carbon or polymer-based inks

- Materials: Medically certified, biocompatible, sterilisable

- Surface integration: flat, curved, textiles

Characteristics

- Ultra flexible, flat, customisable

- Fast signal output upon contact with liquids

- Application examples: Disposable medical products, industrial equipment, packaging

Printed humidity sensors

Composition

- Configuration: resistant & capacitive

- Substrate: PET, PEN, Polyimid, TPU

- Joints: Contact pads, FPC, ZIF-Tails

Characteristics

- Stable within the range of 15-85% relative humidity

- Integration: Embedded or surface-mounted

- Manufaction: Roll-based or sheet-based

For which manufacturers or OEMs are humidity sensors suitable?

The printed humidity sensors are especially suitable for:

- OEM manufacturers in the fields of smart buildings, medical technology, packaging logistics and automotive.

- Developer of smart wearables and medical applications, e.g. for wound moisture monitoring.

- Manufacturer of flat roof systems or membrane structures with integrated leakage monitoring.

- Logistics companies that need to protect sensitive goods from moisture damage.

- Industry partners who rely on scalable, integrable sensor solutions.

Our humidity sensors can be customised with OEM specifications and are ideal for automated manufacturing and large scale productions.

New sensor technologies

Point of contact:

Danny Nitzsche

Would you like advice on your printed electronics products?

Use our contact form now or call us directly!

Our experts can help you immediately.

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com