Do you have any questions?

How could printed electronics improve your products? Get a free, no-obligation quote now!

Point of contact:

Danny Nitzsche

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com

printed electronics – Innovative solutions with printelectric®

Printed electronics enable flexible, lightweight and customizable electronic solutions for a wide range of applications. The technology opens up innovative applications in areas such as healthcare, automotive, smart building, industry, security and vertical farming.

These include flexible sensors, intelligent building technology and interactive surfaces. We use printed electronics to develop solutions that are precisely tailored to the respective requirements and can be easily integrated into existing products and processes.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Printed electronics for smart and customisable applications

Versatile applications for our products

Printed electronics open up new possibilities in the automotive sector for space-saving, lightweight, and flexible applications. They enable, among other things, integrated sensors, touch-sensitive surfaces, and functional films that can be seamlessly integrated into both vehicle interiors and exteriors. In this way, innovative solutions for comfort, safety, and functionality in vehicles are created.

In healthcare, printed electronics enable innovative applications such as smart patches for measuring temperature, pH value, pressure, or ECG. Wearable sensor solutions record vital parameters in real time and support track-and-trace systems. In particular, health patches based on TPU offer high wearing comfort and open up new possibilities for precise, continuous health monitoring.

In the field of smart buildings, printed electronics create intelligent solutions for greater safety and efficiency. Foil sensors reliably detect leakages of water, oil, or chemicals and enable early warning. This is complemented by humidity and temperature sensing, which supports precise climate control and can be seamlessly integrated into modern building automation systems.

What is printed electronics?

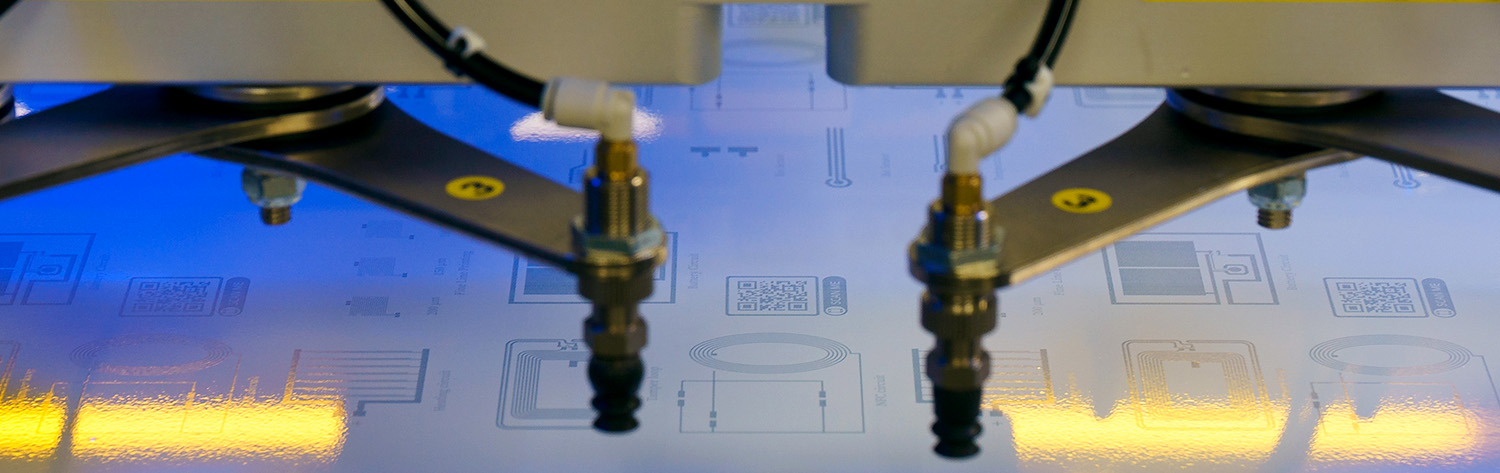

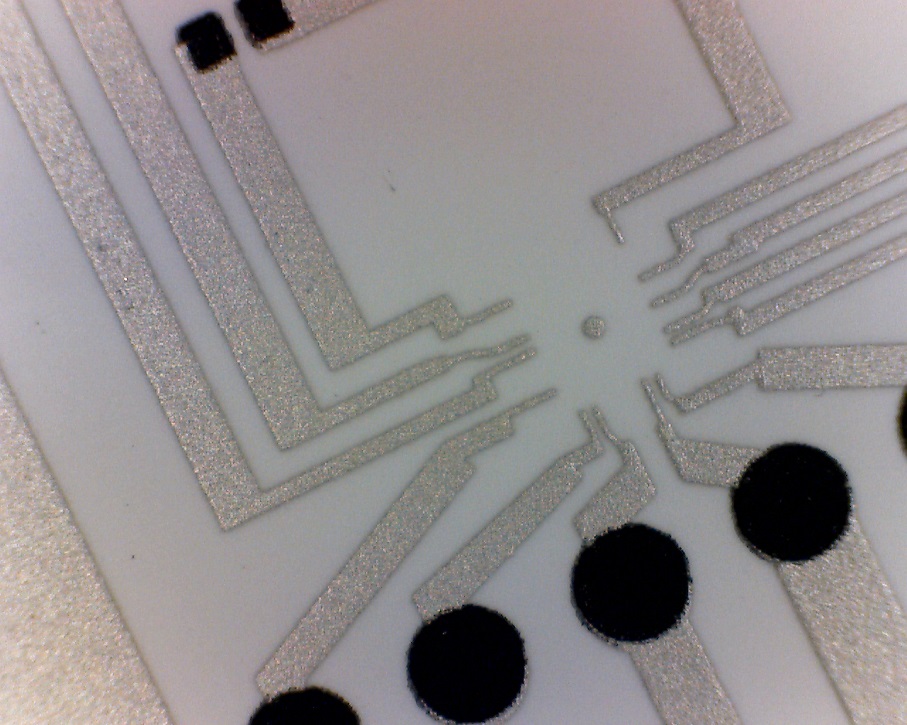

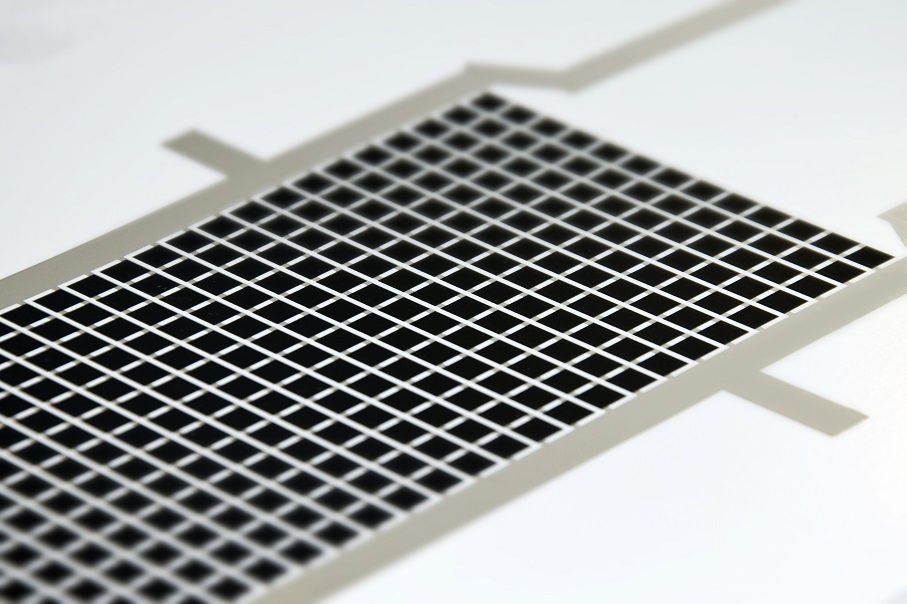

Printed electronics is an innovative technology for manufacturing electronic components using modern printing techniques such as screen printing, flexographic printing, gravure printing, inkjet printing, or roll-to-roll printing. Instead of conventional manufacturing methods, conductive, semiconductive, or insulating functional inks are applied to flexible substrates such as films or paper.

Both organic conductive and semiconductive materials as well as printable inorganic substances are used. When printed in individual layers, they form components with specific electronic properties.

Typical applications of printed electronics

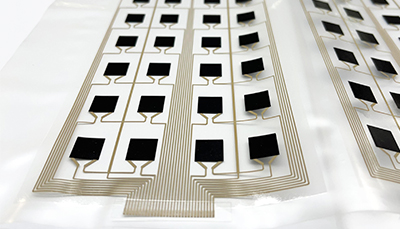

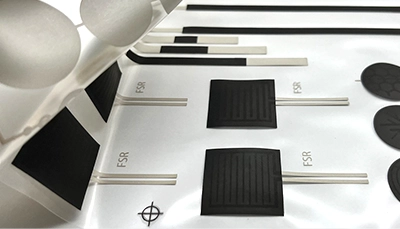

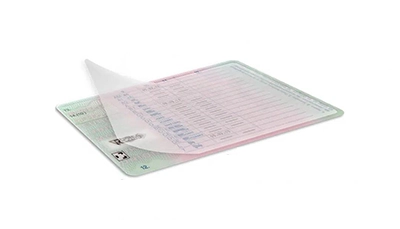

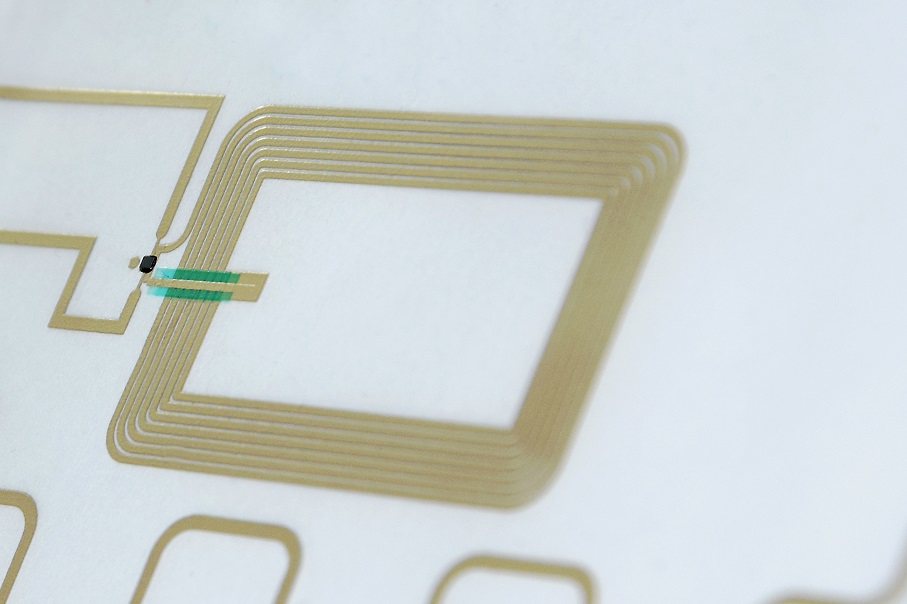

With the help of printed electronics, innovative solutions are possible in many areas. Typical applications include flexible sensors for temperature, pressure, and humidity, stretchable heating foils, and integrated antennas for RFID and NFC. Touch panels, smart displays, as well as printed systems for energy generation and storage are also part of this field. Smart labels, which intelligently enhance packaging and logistics processes, are particularly in demand.

- Flexible sensors (e.g. for temperature, pressure, humidity measurement)

- Stretchable heating foils

- Printed antennas (RFID, NFC)

- Touch control panels and smart displays

- Energy generation and storage (printed solar cells, batteries)

- Smart labels for packaging and logistics

The advantage of printed electronics:

Extremely thin, flexible, and in some cases transparent electronic components open up a wide range of applications. They are used, among other areas, in consumer electronics, packaging technology, the automotive sector, the pharmaceutical industry, the energy sector, and household appliances.

The result is innovative products such as touch sensors, flexible displays, solar cells, light-emitting foils, and smart labels. These fully printed components can be used for capturing and transmitting data within the Internet of Things (IoT).

FAQ – Frequently asked questions about printed electronics

Witte Technology GmbH offers a range of printed electronics products, including printed batteries, NFC antennas, sensor elements, smart packaging, and SmartLabels. In addition, we develop complex components and have introduced innovative digital seals. We are also happy to advise you on customizing solutions for your products.

Printed electronics offer advantages such as compactness, cost and energy efficiency. Applications can be found in many areas, for example in OLED televisions, temperature sensors for food packaging, electronic product labels, ultra-thin and flexible displays, light-emitting foils, and printed sensors for the automotive industry.

At Witte Technology GmbH, experts are ready to answer your questions about printed electronics and offer advice in this area. We can provide you with further information at any time via the contact form or the telephone number.

Contact person

Danny Nitzsche

Would you like advice on your printed electronics products?

Use our contact form now or call us directly!

Our experts can help you immediately.

Tel: +49 25 36 9 91 – 103

Mobile: +49 170 330 84 88

nitzsche [at] witte-technology.com

Your contact from Research and Development

Dr. Philip Renners

Are you interested in a consultation on printed electronics?

Contact us using our form or call us directly!