Do you have any questions?

How could printed electronics improve your products? Get a free, no-obligation quote now!

Point of contact:

Danny Nitzsche

Tel: +49 25 36 9 91 – 103

Mobil: +49 170 330 84 88

nitzsche [at] witte-technology.com

Printed electronics for medical technology

Witte Technology GmbH develops electronic components for medical applications. We combine modern printing technologies with many years of experience in conductive inks and carrier materials. Our solutions are suitable for diagnostics, wearables and smart packaging.

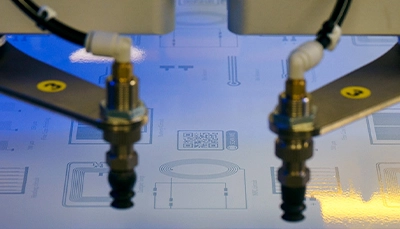

We rely on screen printing, flexographic printing and digital printing. This enables us to manufacture functional components that support medical certifications and can be integrated into your existing systems.

Flexible sensor solutions for temperature and humidity detection.

Our reliable sensors measure body temperature and detect moisture on the skin at an early stage. They are used in wearables, wound care and textiles for nursing and medical care.

Depending on the application, the sensors are washable and reusable or can be used as disposable products.

Our Sensor Technologies:

| Sensor type | Description |

|---|---|

| Temperature sensor: | Thin, stretchable, and skin-friendly. Measures body temperature directly on the skin. |

| Moisture sensor: | Flexible, robust, and formable. Detects moisture on the skin at an early stage. |

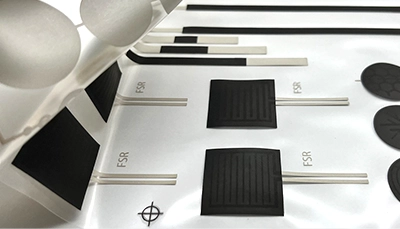

| Pressure sensor: | Pressure-sensitive elements used in applications such as bed occupancy detection, compression, and similar. |

| Printed ECG and biosignal patch: | Ag/AgCl electrodes for precise, comfortable monitoring of physiological signals. Individually customizable for… |

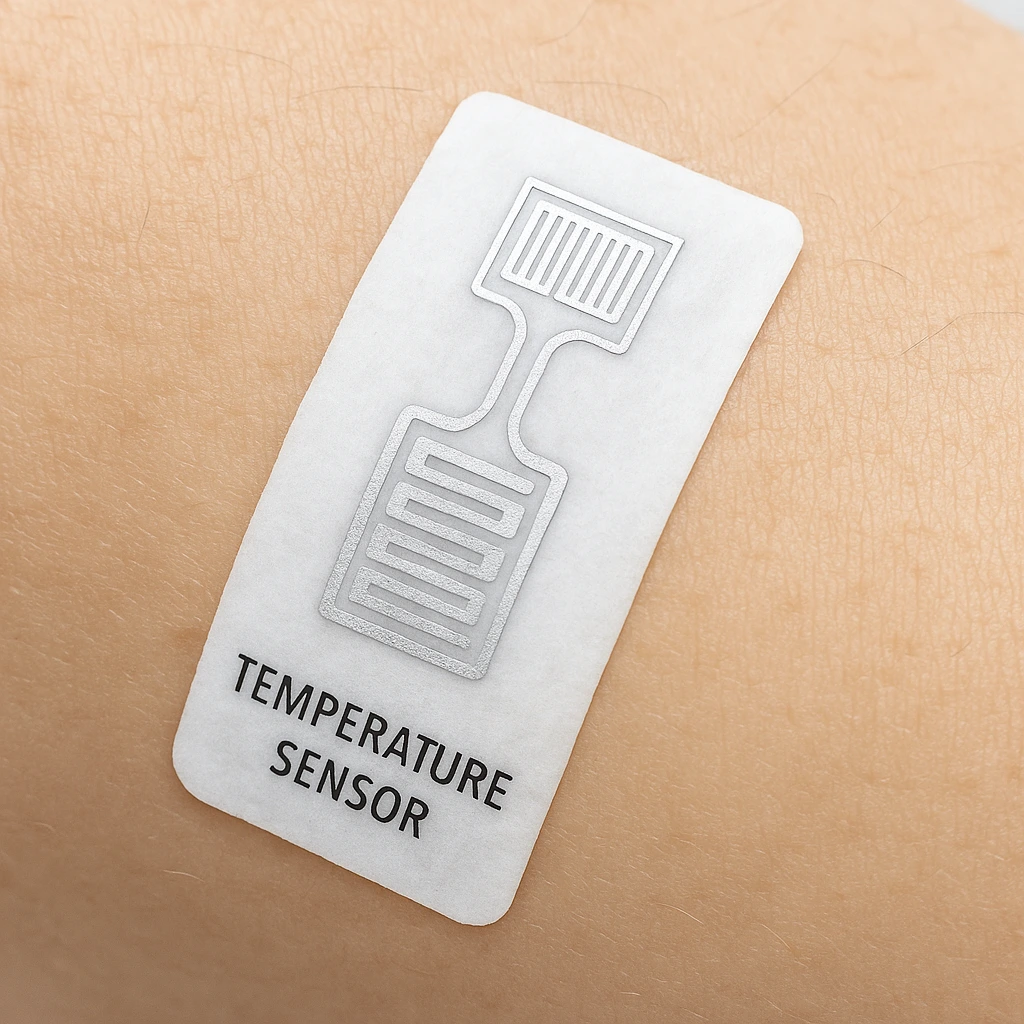

Temperature sensor for medical applications

The sensor continuously measures body temperature. It consists of a stretchable sensor material, a skin-friendly adhesive and a soft non-woven fabric.

The sensor works by measuring resistance. As the temperature rises, the electrical resistance decreases. The built-in NTC material is highly sensitive.

- Measuring range: 0 to 80 °C

- Stretchy and comfortable to wear

- Connection via crimp or FPC connector

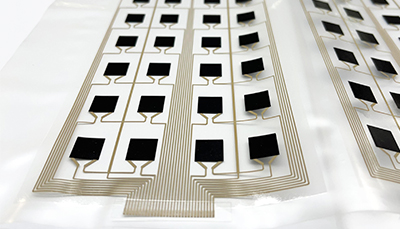

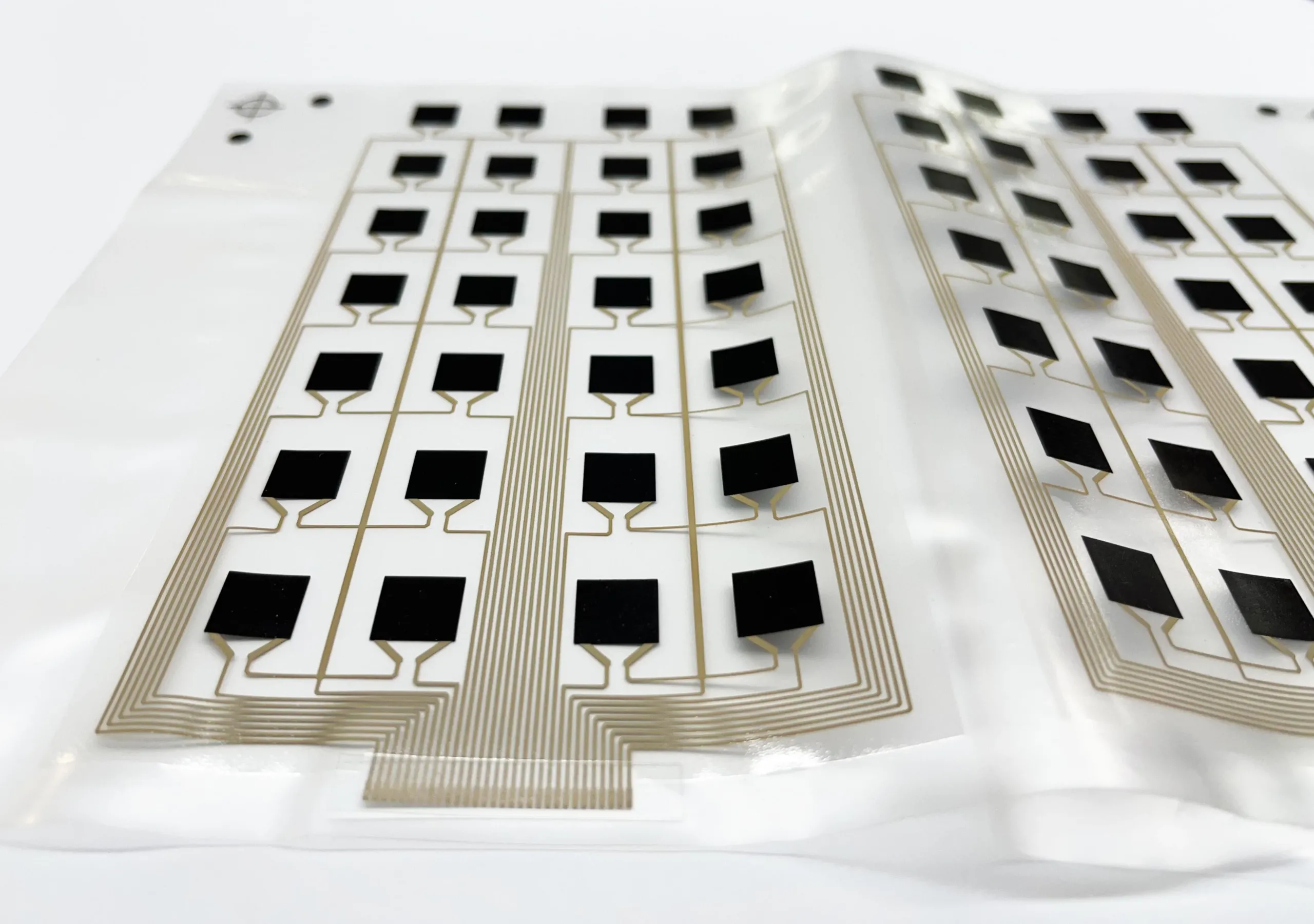

Humidity sensors for skin monitoring

Witte Technology offers an intelligent moisture sensor that is applied directly to the skin.

The sensor is flexible and adapts to any part of the body. It can be designed in different sizes depending on requirements. It is robust, can withstand stress and is protected against liquid inflow. The sensor detects moisture, for example in cases of incontinence, wounds or under bandages.

How does this technology work?

The sensor detects liquid through changes in resistance values. The material used is carbon-based, environmentally friendly and efficient.

- Sensor length: from 10 mm to 2 m

- Production: as single sheets or roll printing

- Stretchability: 10–50%

- Washable and reusable

Measure humidity and moisture with our sensors

Printed sensors for further medical applications

Our technology enables further applications in medical technology. We develop sensors for:

- Pressure measurement, for example in beds or bandages

- Disposable electrodes for diagnostics (e.g. Ag/AgCl)

The sensors are energy-efficient, flexible and tailored to clinical requirements.

Materials and protection systems

We work with

- Silver and silver chloride inks for high conductivity

- Carbon-based inks for simple applications

- Protective inks for sealing against moisture and abrasion

All materials are carefully selected and documented. This is how we support our customers in certification processes.

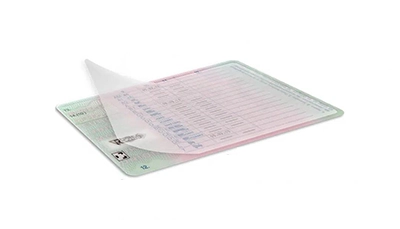

Intelligent packaging solutions

We integrate printed features into medical packaging:

- Moisture indicators for storage and hygiene

- RFID or NFC antennas for tracking and communication

- Printed test indicators for safety and control

All components are compatible with packaging lines and sterilisation processes.

Our printing technologies

- Screen printing: High precision and defined layer thickness

- Flexographic printing: Efficient for high volumes in roll printing

- Digital printing: Variable and ideal for prototypes

We offer post-processing services such as lamination, drying, perforation and stacking. From prototypes to series production, anything is possible.

FAQ – Frequent Questions regarding our sensor products

We have in-house capabilities for manufacturing printed sensors for:

- Leakage and moisture detection

- temperature monitoring

- Pressure-sensitive applications

- Moisture control and detection

- Further customer-specific sensors available on request

Each solution is developed using appropriate material systems and validated printing processes to ensure reliability in clinical and industrial applications.

Yes. We offer small series for prototyping, functional testing and development support. After successful qualification, we can scale up to industrial sheet-to-sheet or roll-to-roll production.

We use materials that are generally accepted for medical applications. Although we do not certify end products, we support customer-led certifications with material data sheets, batch tracking and process documentation.

We print antenna structures and circuits that can be integrated with RFID or NFC tags. Applications include smart medical labels, inventory management and sensor-based communication.

We supply printed components, including:

- Moisture and leak sensors

- Temperature, pressure and humidity sensors

- Electrode structures (e.g. Ag/AgCl) for diagnostic applications

- Conductive circuits and contact layers

- Smart label inserts or printed packaging features

- Leak sensors for liquids to improve patient safety

- Humidity sensors for wearables and packaging

- Skin-friendly temperature and pressure sensors for contact-based measurements

- Humidity sensors for climate control in medical kits

- Printed ECG and customised biosignal electrode systems for diagnostic applications

We focus on the manufacturing of printed functional components, including sensors, electrodes, and conductive tracks. While we do not supply batteries or ICs directly, we work closely with our trusted hardware partners to support system integration and ensure compatibility with your electronic assemblies.

Point of contact:

Danny Nitzsche

Would you like advice on your printed electronics products?

Use our contact form now or call us directly!

Our experts can help you immediately.

Tel: +49 25 36 9 91 – 103

Mobile number: +49 170 330 84 88

nitzsche [at] witte-technology.com

Your contact in research and development

Dr. Philip Renners

Are you interested in consulting on printed electronics?

Contact us using our form or call us directly!